The Importance of the Cylinder Block in Engine Performance

The cylinder block in engine design is a crucial component that significantly influences the performance, durability, and overall efficiency of a diesel engine. In this comprehensive article, we will explore the function of the cylinder block, its construction, and its impact on engine performance.

Understanding the Basics of the Cylinder Block

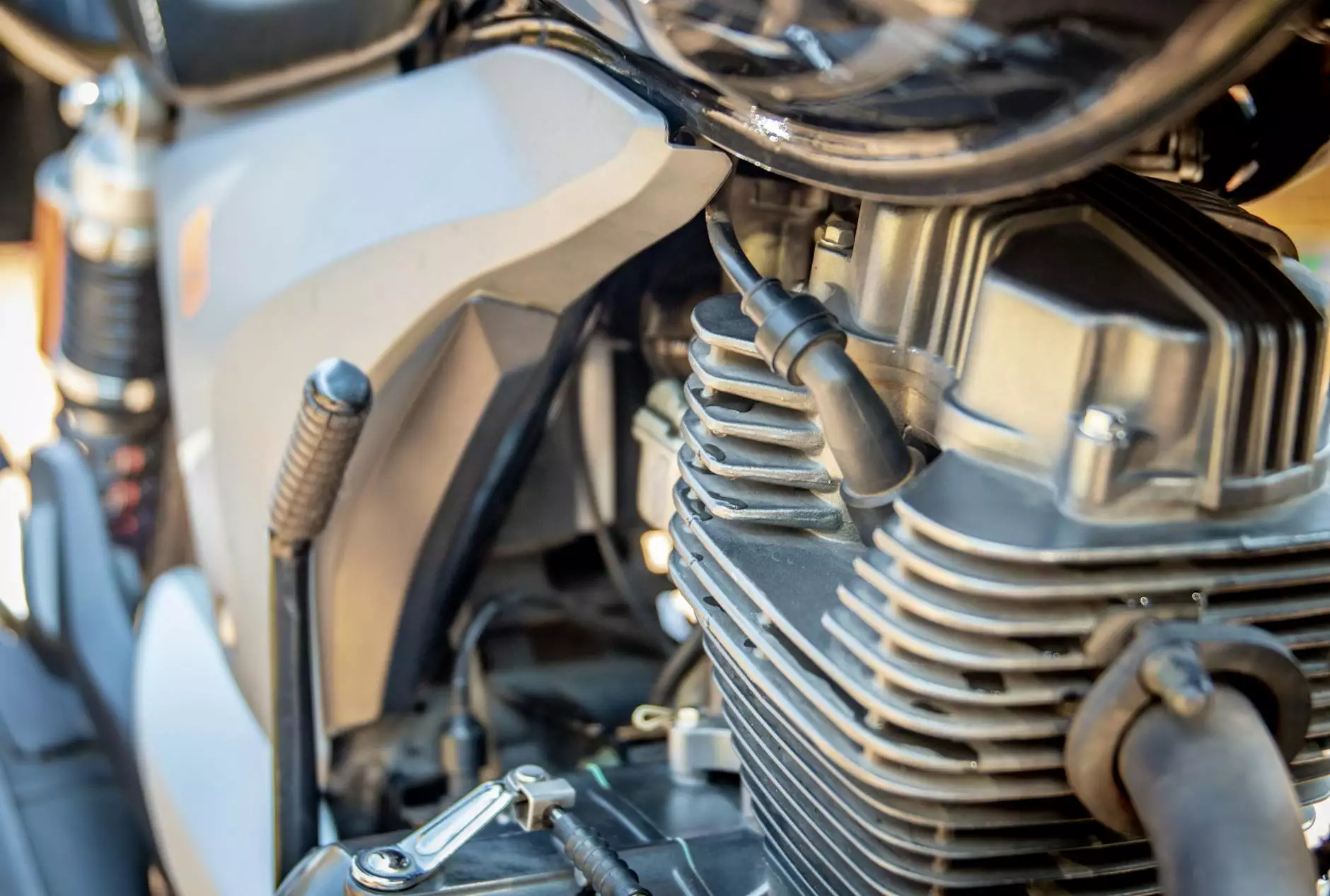

The cylinder block serves as the main structure of an engine, providing housing for the engine's cylinders. It's typically made of cast iron or aluminum, materials chosen for their durability, strength, and weight properties. The cylinder block plays a pivotal role in accommodating various engine components including:

- Cylinders: Where the combustion of fuel occurs.

- Pistons: Components that move up and down within the cylinders.

- Crankshaft: Converts linear motion from the pistons into rotational motion.

- Camshaft: Controls the opening and closing of valves.

The Role of Cylinder Block in Engine Functionality

The cylinder block in engine systems has several critical functions:

- Structural Integrity: It provides a solid frame that supports all internal components.

- Heat Dissipation: During combustion, high temperatures are generated. The cylinder block helps dissipate this heat effectively.

- Compression Seal: The cylinder block must form a tight seal with the head to maintain the pressure needed for efficient combustion.

- Oil Circulation: Many designs allow for the circulation of oil through the block to lubricate the moving parts.

Types of Cylinder Blocks

Cylinder blocks can be classified into several types based on their construction and design:

- Inline Cylinder Block: Contains cylinders arranged in a straight line. Common in many four-cylinder engines.

- V-Type Cylinder Block: Features cylinders arranged in a V configuration, often found in larger engines.

- Flat Cylinder Block: Also known as a horizontally opposed design. Found in some performance vehicles.

Cylinder Block Design Considerations

When designing a cylinder block in engine, several considerations are taken into account to enhance performance:

- Material Selection: Balancing weight with strength is paramount. Using advanced alloys can yield better performance.

- Cooling System Integration: Proper channels must be designed to facilitate effective cooling.

- Manufacturing Techniques: Innovative production methods like die-casting or machining can improve material integrity.

Impact of the Cylinder Block on Diesel Engine Performance

The cylinder block in engine systems directly affects the performance metrics of diesel engines:

1. Engine Power and Torque

The design of the cylinder block influences the engine's ability to generate power and torque. A well-designed cylinder block allows for higher compression ratios, contributing to better power output.

2. Fuel Efficiency

Fuel efficiency can also be improved through optimized cylinder designs that allow for better combustion processes. This efficiency directly correlates to the design and integrity of the cylinder block.

3. Durability and Longevity

High-quality materials and construction in the cylinder block lead to increased durability, reducing the frequency of repairs and replacements for the engine.

Maintenance of the Cylinder Block

Regular maintenance of the cylinder block in engine systems is essential to ensure longevity and efficiency. Here are some maintenance tips:

- Regular Oil Changes: Ensures contaminants do not build up, which can wear down the internal surfaces.

- Inspect for Cracks: Regular checks for cracks can prevent catastrophic failures.

- Cooling System Maintenance: Keeping the cooling system in check prevents overheating and extends the life of the cylinder block.

Common Issues Affecting the Cylinder Block

Several issues can arise with the cylinder block, including:

- Overheating: Can cause warping of the block.

- Cracking: Often results from thermal stress or manufacturing defects.

- Oil Leaks: May occur from failing gaskets or seals.

Future Innovations in Cylinder Block Design

The future of cylinder block in engine technology is poised for significant advancements. Innovations may include:

- Lightweight Alloys: Development of newer composite materials that reduce weight while maintaining strength.

- 3D Printing: Offering the potential for complex designs that are currently infeasible with traditional manufacturing techniques.

- Advanced Cooling Technologies: Innovations in heat management can further improve performance and longevity.

Conclusion: The Vital Role of the Cylinder Block in Engine Technology

In summary, the cylinder block in engine systems is an integral part of diesel engine performance. Its design and maintenance not only affect the engine’s power and efficiency but also its operational lifespan. With ongoing advancements in technology, the future holds even greater potential for enhancements in cylinder block design and functionality.

At Client Diesel, we understand the critical nature of diesel engine components, including the cylinder block. We are proud to provide high-quality diesel engine parts and are dedicated to being your reliable spare parts supplier. Our expertise ensures that your engines perform optimally, contributing to the efficiency and reliability of your operations.